Optimize CEA Lighting, What Should You Do?

CEA (Controlled Environment Agriculture) is still new to some growers. A successful CEA requires lots of practice and training. In CEA facilities, lighting plays an important role in quality, yield, and production of crops. Moreover, high energy costs and unsatisfactory lighting performance prompt growers to optimize their CEA lighting. They are looking for a more efficient CEA lighting solution to help them reduce electricity bills and maximize the return on investment. There are various lighting options in the horticulture lighting market. HID and LED are the common choices of most growers. Optimizing CEA lighting could mean switching from HID to LED grow lights, or retrofitting order HID to new HID luminaires. Whether replacing or refitting the existing lighting system, CEA lighting optimization requires a clear goal and thoughtful considerations.

Today, we will show you more details about what you should do to optimize CEA lighting.

What is CEA

CEA is an acronym for ‘Controlled Environment Agriculture’. Over the years, CEA is gaining growing attention under the condition of decreasing water and arable lands. With the development of technologies, CEA is becoming more and more sustainable and profitable. Greenhouses and indoor farms are important parts of the CEA industry. The common feature of CEA is that growers control all factors associated with plant growth, such as temperature, light, humidity, carbon dioxide, and airflow. For example, CEA can reach ester lily for the market by controlling temperature. By providing the optimal growing conditions for plants, grower can reap higher productivity and better quality.

Knowing CEA lighting options

Lighting solutions for CEA crops are based on facility and crop type. Different lighting conditions in greenhouses and indoor farms require different light intensity and periods. Similarly, lighting requirements vary by crop type. For every crop and facility, there is a high performance lighting solution.

Facility type

Greenhouses and indoor farms have different light needs. Sunlight can be transmitted through transparent glasses, and crops in greenhouses absorb natural light during the day. Therefore, greenhouses require supplement lighting to maximize quality and yields. Furthermore, the high greenhouses may use top lighting and inter-lighting to meet the lighting needs of vine crops. In contrast, artificial lights is the sole light source for indoor farms. The vertical farms install tubes or multi-bar lighting on the top of each tier of racks. Since grow lights in indoor farms work for a long period, lighting solutions for indoor farms must be energy-efficient.

Crop type

Different crops result diverse lighting options. Some crops require high light intensity while others do not. Even the same crop in different growing stages has different lighting needs on light intensity, spectrum, and duration. Dimmable LED grow lights could be an ideal solution to provide different light levels for crops throughout their life cycle. For flowering crops, CEA facilities use photoperiod lighting to trigger flowering and make them available earlier in the market.

Optimize lighting for CEA facilities

After understanding CEA lighting options, you may know CEA crops can benefit from various light treatments. What you should do to optimize CEA lighting is to determine your cultivation goal first. Then, the crop you grow and your facility type will inform your choice of lighting fixtures, light recipe, and fixture layout.

Determine your goals

The goal is the basis of successful CEA lighting optimization. Some growers may want to increase lighting efficiency and save energy costs. Some may want to improve crop quality or prompt flowering. The goal absolutely impacts following luminaire selection and lighting design. A determined goal allows you to construct a lighting system to achieve your expectations.

Retrofit HID to LED

One of the common ways to optimize CEA lighting is switching lighting fixtures from HID to LED. Incentives of this tends are more energy savings, greater spectral flexibility, lower heat, longer lifespan, and the ability to dim lighting intensity. Whether for increasing energy or lighting efficiency, LEDs have better performance than HID lights. Although the initial cost of replacing HID lights with LED might be higher than retrofitting order HID lights to new lights, the long lifespan and lower operating cost offer a higher ROI.

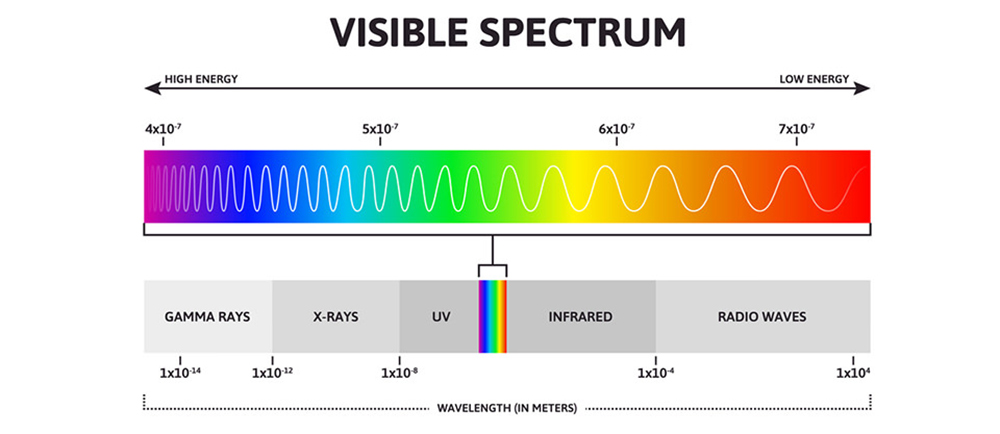

Choose light spectrum

Providing the appropriate light spectrum for plants is critical in lighting optimization. The customized spectral quantum distributions meet plants’ needs precisely. LED grow lights are the only type of artificial light that has spectral flexibility. As an LED grow light manufacturer, Atop can provide unique light spectrum targeting specific plant responses. For most greenhouses, red and blue LEDs are the popular options for supplementing light for plants. When it comes to indoor farms, full spectrum (white light) LED grow lights are the best option. The full spectrum LED grow lights offer plants the light similar to natural sunlight. And they can be used for all growing stages. Other supplemental lights like UV lights, green lights, and far-red lights also benefit certain stages of growth.

Calculate mounting height

Mounting height affects the light levels plants received at the canopy level. Mounting height of artificial lights does not affect the total amount of light, but the lighting uniformity and lighting intensity. The higher grow lights are placed above plants, the lower light intensity plants receive (in the same area). Excessive lighting including over light intensity and duration will cause plant burns and drying. Since LED grow lights generate less heat than HIDs, they can be placed closer to the plant canopy. But the specific mounting heights vary from power of artificial light and crop type.

Light intensity and uniformity

Providing moderate light intensity and maintaining uniformity should be taken into account in CEA lighting optimization. Uniform light levels contribute to consistent light intensity. The layout of lighting fixtures greatly affects uniformity. Lighting manufacturers provide a PPFD map which shows the minimum PPFD, maximum PPFD, and the uniformity. You can check out the PPFD map and know whether the lighting fixture targets the lighting levels for plants. A light plan can provide accurate simulation of the quantity and layout of artificial lights required for your locations and business goals, as well as targeting light intensity and uniformity. If you want to replace your existing lighting system to LEDs, contact us for a free light plan.

Consider interactive effects

Les’ t recap the concept of CEA. CEA means Controlled Environment Agriculture. The common feature of CEA is that growers control all factors associated with plant growth, such as temperature, light, humidity, carbon dioxide, and airflow. Therefore, you should consider the interactive effects on the growing environment like the HVAC system. LED grow lights produce less heat than HID lights. To keep your facility at the same temperature, more heating machines may be required in colder climates. Similarly, less HVAC capacity for cooling may be required during warmer climates.